Ceramic Injection Molding Applications

The CIM technique has essentially endless uses. Ceramic produces items that are highly corrosion resistant, wear resistant, and have a long lifespan due to its high flexural strength, hardness, and chemical inertness. The electronic assembly, tool, optical, dentistry, telecommunications, instrumentation, chemical plant, and textile sectors all use ceramic materials.ceramic injection molding

One of the most often utilized materials in ceramic injection molding is alumina ceramic. High degrees of electrical insulation, heat and corrosion resistance, and mechanical strength are among the characteristics. Zirconia ceramics: Considered to be the strongest ceramic substance, zirconia is employed in a wide range of industries, including the medical and dentistry fields. Due to its characteristics, zirconia has a remarkable level of damage tolerance and is very resistant to wear and fracture. Additionally, it is remarkably stable under pressure. The procedure known as ceramic injection molding produces custom ceramic pieces using an injection mold technique that is similar to that used with plastics (CIM). A pelletized combination of alumina powder and a few binders is heated beforehand and then pushed under extreme pressure into a specifically designed mold to produce components that precisely fit the part design requested by the customer. After being removed from the mold, the part goes through a variety of further processes, including sintering at a high temperature.

The procedure known as ceramic injection molding produces custom ceramic pieces using an injection mold technique that is similar to that used with plastics (CIM). A pelletized combination of alumina powder and a few binders is heated beforehand and then pushed under extreme pressure into a specifically designed mold to produce components that precisely fit the part design requested by the customer. After being removed from the mold, the part goes through a variety of further processes, including sintering at a high temperature. We will work with you through all phases of project development – from requirement planning, tooling design and mass production, to FOT and manufacturing, through to the shipping . We can make any precision metal products, such as metal auto parts, electronic parts, 3C electronic parts, precision medical parts!

We will work with you through all phases of project development – from requirement planning, tooling design and mass production, to FOT and manufacturing, through to the shipping . We can make any precision metal products, such as metal auto parts, electronic parts, 3C electronic parts, precision medical parts!

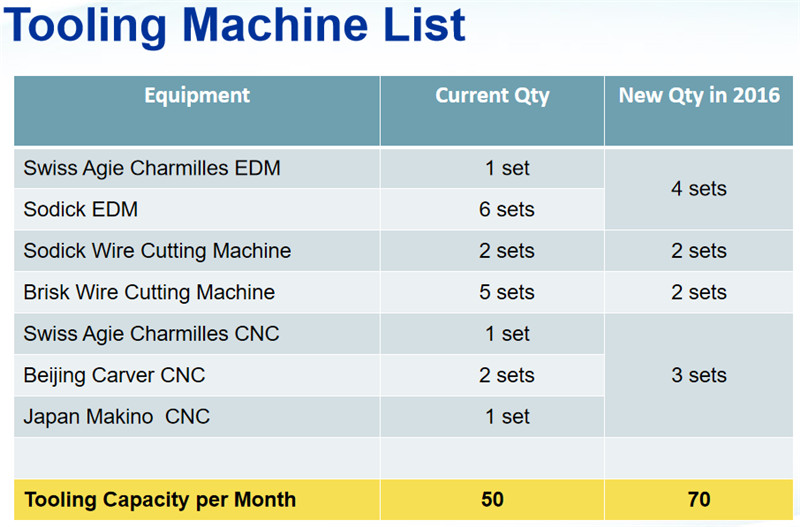

One-stop Metal parts supplier in ChinaOur core manufacturing equipment is imported directly from Germany.We have 15 engineers in our R&D centre, all of them are doctors or professors from University of Science and Technology of China.Strict Quality Control, Rigorous product inspection after mass production

One-stop Metal parts supplier in ChinaOur core manufacturing equipment is imported directly from Germany.We have 15 engineers in our R&D centre, all of them are doctors or professors from University of Science and Technology of China.Strict Quality Control, Rigorous product inspection after mass production